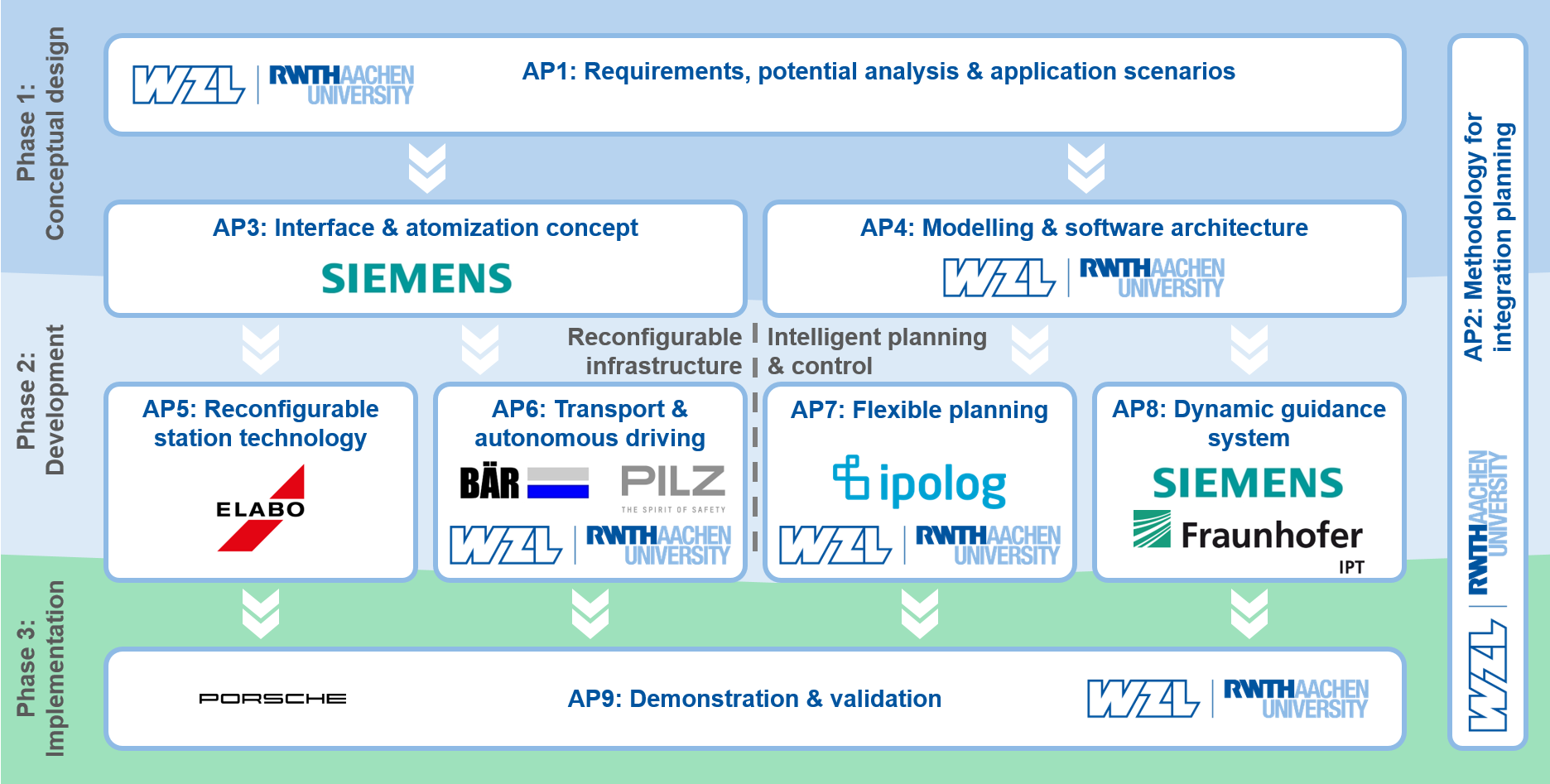

Project structure

The research project is being carried out in nine work packages. These are divided into three phases: Conception, development and implementation. The starting point is formed by the determined target values and restrictions in the first work package as well as the defined application scenarios. Based on this, in the third workpackage, all hardware and software interfaces are going to be determined within a defined automation architecture. Furthermore, a basic model is created in the fourth work package, containing all data for the combined planning and controlling. In the subsequent development phase, the fifth work package consists of the design of a system of flexible intralogistics and station technology modules with an integrative interface concept. The sixth work package contains the development of an overall concept for the automation of vehicle logistics. Simultaneously, in the seventh work package, a software being as consistent as possible is developed, which flexibly creates an optimal assembly system with a defined production plan. In the eighth work package, the research project focuses on the development of a dynamic control system for the optimal control of the main material flow and resources. In the final ninth work package, the results are validated and illustrated in a physically tangible production environment. In order to support the whole research project, a methodology for integration planning is developed in the second work package.