Project

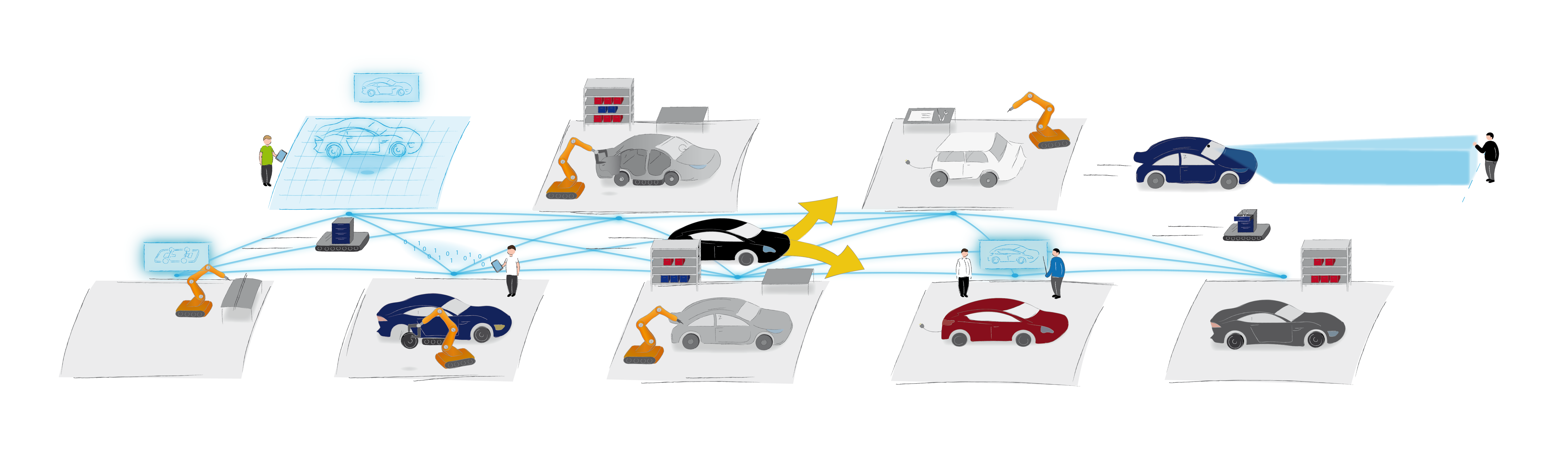

The AIMFREE research project aims at the parallelization of workstations and the implementation of versatility and flexibility in the final assembly of automobiles.

A key aspect of the project is the holistic consideration of all necessary aspects of an agile assembly system. In addition to the agile system itself, this includes the initial system design as well as planning and control. Concrete results will be validated both in real assembly plants of the project partners from the automotive industry and in a demonstration factory. In this way, application-oriented research is guaranteed. The joint work of research institutes, system providers and car manufacturers in the consortium ensures that all necessary competences and experience are combined in this project.

The research project is being carried out in nine work packages. Based on methodical and theoretical fundamentals, an automation architecture and a basic data model will be conceptualized first. Next, station technology modules enabling reconfiguration and an overall concept for the automation of vehicle logistics will be developed. At the same time, a software solution and a dynamic control system for intelligent planning and control will be developed. The results obtained will be validated in their entirety and illustrated in a demonstration environment.

The development is being carried out jointly by the Machine Tool Laboratory (WZL) of the RWTH Aachen University as consortium leader of the project, the Fraunhofer Institute for Production Technology (Fraunhofer IPT) and the following industrial partners: Porsche AG, ipolog GmbH, Siemens AG, ELABO GmbH, BÄR Automation GmbH, Pilz GmbH & Co. KG.